Product search

POPULAR CATEGORIES

Best sellers

WATSON A5 VALUE-FOR-MONEY NOTE BOOK & PEN.

Price Range: £2.99

AKAW THERMAL INSULATED STAINLESS STEEL METAL BOTTLE - 600ML.

Price Range: £14.99

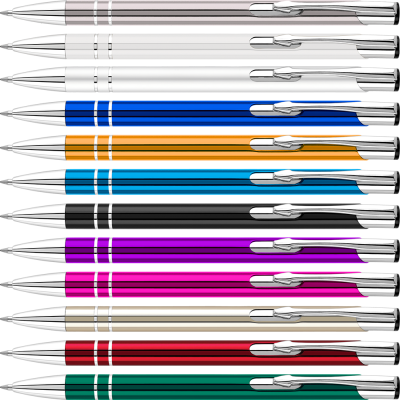

ELECTRA ENTERPRISE BALL PEN.

Price Range: £0.74

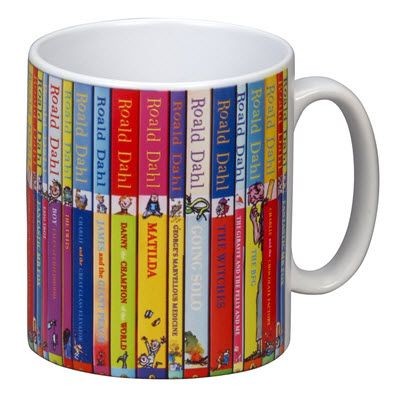

CAMBRIDGE SILK MATT DYE-SUB MUG in White.

Price Range: £5.99

HENBURY HEAVY POLY-COTTON PIQUE POLO SHIRT.

Price Range: £8.99

ECO RANGE - ECO KRAFT CUBE - RETRO SWEETS.

Price Range: £2.99

Branding Options

Artwork Guidelines

When submitting artwork for your merchandise orders we can accept it in almost any type of electronic file, Mac or PC. Please feel free to email our studio with any questions that you would like us to answer or files that you would like us to check over for suitability.

Please forward your artwork as early as possible so that we can advise you on the best way that you logo can be presented on your chosen promotional item. When you contact us one of our trained staff will be able to advise you on the best method that can be used to print your logo and message. They will advise one of the following technologies that are available to us:

Screen Print

A screen print is the application of a single colour at a time through a custom made 'template' or 'stencil' onto a flat or curved surface. A second or more pass would need to be made to apply additional colours from the design. Screen print costs vary depending upon whether or not an automated machine process is possible, semi automated process is employed or traditional manual technique used. Screen printing is great for most three dimensional objects made from plastics, wood, metal, textiles, glass and ceramics.

Tampo or Pad Print

The most effective way of applying up to 4 colour process onto flat, curved or recessed areas. Ink is applied from an etched plate via a rubberised pad. This in turn applies ink under correct pressure lifted from the plate. Tampo or pad printing is great for just about every desk top item. Anything made from firm, hard or semi soft materials can be printed whether they are flat or curved, recessed or indented.

Acid Etching

Similar to screen printing but instead of using coloured ink an abrasive acid chemical is applied though the template instead. This chemical erodes and affects the products surface leaving a contrasting area. Acid etching is great for glass, metal, wood and ceramics providing an 'embossed' look.

Engraving

Applied with a powerful laser or via a diamond tipped tool, engraving will literally burn or scratch into your chosen product leaving a mark that will outlive any other print or branding technology in normal general use. Laser engraving is great for chrome or stainless steel, glass, crystal and wooden objects.

Litho Process Printing

Litho process printing can be used to give your design greater depth through the use of tints, tones and gradients. A litho process can use as many spot colours as you like.

Litho process is great for paper and cardboard items, poly, textiles, larger flatter surfaces made from PVC and plastics.

4 Colour Process Printing

Cyan, magenta, yellow and black ink is used to produce a final finish as good as a photograph. 4 Colour process printing is great for paper, cardboard, textiles and other flat surfaces including PVC and plastics technologies.

Transfer Printing

Transfers are printed up to 4 colour process onto a flat, vinyl material. It is then applied to your chosen item via chemical adhesion and heat application. Transfer printing is great for ceramics, glass, textiles, PVC and plastics. UK made stress item bags.

Digital Print

Allows files to be printed direct from the computer onto material removing the need for plates or film. Digital printing is great for paper, plastics and textiles providing short runs and a quick turn around.

Hot Foil Blocking

Application of coloured foil onto leather or PVC, in particular diaries and desk sets.

Hot foil blocking is great for leather diary products.

Embroidery

A way of stitching your design into garments, bags, vinyl and other thin materials. Clarity will never be as crisp as print onto for example plastics, but outlasts, and outperforms print onto garments and just seems the right thing to do onto clothing.

Embroidery is great for clothing, textiles, thin PVC and other flat, thin or soft surfaces.

Woven

Custom set loom to create a garment or bag from scratch to your specific design. A polo shirt with two different coloured arms, club tie and ladies scarf set, towel or custom made neck ladel are but a few examples. Great for textiles and woven neck labels.

Labelling

Application of label to finished product. 4 Colour process and litho process' employed to print labels to specific size on materials such as paper, vinyl and plastics. Great for application of 4 Colour process design to product that would not ordinarily be able to have print process applied to it.